Innovative Process Solutions for the Biodiesel Industry

Cold Filter Plugging

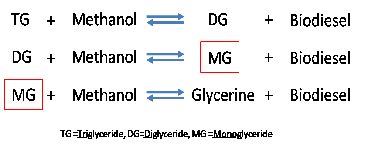

Unreacted intermediates, in particular saturated monoglycerides (MG) can form crystals in biodiesel-diesel blends in cold conditions resulting in fuel filter plugging issues.

These intermediates are very difficult and expensive to separate from the final biodiesel product.

Although the current ASTM standard does not include a maximum level for MG, the New ASTM Biodiesel No.1 Standard sets MG limits of 0.4%. Several large blenders are even now requiring MG levels below 0.3%.

Many convention processes can not meet this new standard and the more stringent blenders specifications without distillation of the final product.

BDR’s process can achieve this requirement with a variety of feedstocks without the need for distillation.

Chemistry

![]()

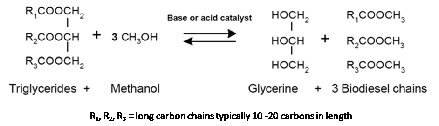

The production of biodiesel, or alkyl esters, is well known. The general process, called “transesterification”, is depicted below. A fat or oil (triglyceride (TG)) is reacted with an alcohol, like methanol, in the presence of a catalyst (sodium or potassium hydroxide) to produce glycerine and methyl esters or biodiesel. The methanol is charged in excess to assist in quick conversion and recovered for reuse.

Transesterification

The transesterification of lipids is an equilibrium reaction and is limited by the amount of catalyst, the methanol-to-oil ratio and temperature. The oil in methanol forms an emulsion (similar to oil and vinegar in a salad) and requires significant mixing. At least three reaction steps are required to fully convert lipids into ASTM biodiesel.

A Three-Step, Catalytic, Reversible Reaction